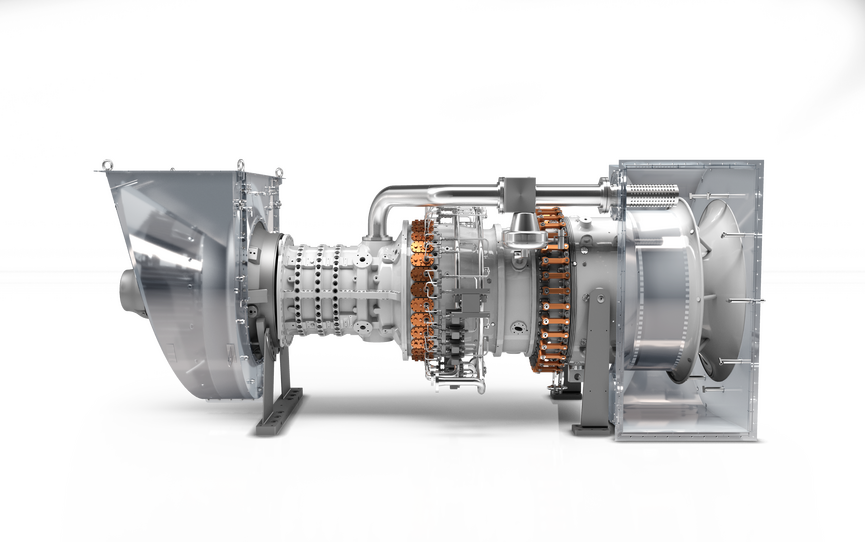

Baker Hughes NovaLT™ gas turbines are setting new standards in efficiency, availability, reliability, and flexibility, while minimizing total costs of ownership.

With a rapid 45-day installation window, an outstanding 35,000-hour mean time between maintenance, and 24-hour engine swap capability, Baker Hughes’ NovaLT™ turbines set the benchmark for functionality, availability, reliability, and high performance.

NovaLT™ turbine manufacturing processes—including factory acceptance tests—have achieved significant reductions in greenhouse gas (GHG) emissions: 16% lower on average for the NovaLT™12 and 35% lower for the NovaLT™16, compared to legacy technologies like the PGT10 turbine. Additionally, these gas turbines are engineered to operate at 9 ppm NOx @15% O₂ when running on natural gas (from 50% to 100% load), supporting both mechanical drive and power generation applications.

The NovaLT™16 turbine can start up and burn gas blends up to 100% hydrogen. It can also switch from natural gas to blends, or 100% hydrogen, with no hardware changes.